A leading domestic food group, specializing in casual snacks and frozen foods, with nationwide business, needs to upgrade its warehousing system to match its tens-of-billion-yuan production and sales scale, ensuring food storage freshness and supply chain turnover efficiency.

The original warehousing had high error rates in manual sorting, and with multiple categories and fast batch updates of casual and frozen foods, there were strict requirements for inbound/outbound timeliness and shelf-life management; warehouse space utilization was insufficient, unable to support the expansion of new categories, so an intelligent stereoscopic warehouse was urgently needed to realize automated sorting, intelligent shelf-life control, and high-density storage.

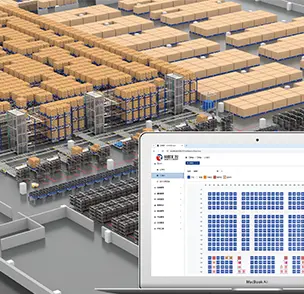

Equipment: Configured multiple low-temperature adaptive stacker cranes (using low-temperature resistant components and anti-frost design), combined with an intelligent conveyor system, to realize fully automated “aisle access + trunk conveying” flow.

System: Deployed a WMS with a shelf-life management module, automatically identifying batches and triggering shelf-life warnings, and combined with WCS to realize intelligent equipment scheduling, prioritizing the handling of goods with approaching expiration dates.

Storage: Customized rack layout, compatible with the storage of different specifications of food, using the vertical operation capability of stacker cranes to achieve high-density storage of more than 15,000 positions, with space utilization increased by 60% compared to traditional flat warehouses.

Multiple food categories (casual, frozen) have large differences in storage specifications, and shelf-life management is complex, requiring precise batch and shelf-life control.

The storage environment of some frozen foods (below -18℃) has extremely high requirements for the cold resistance and stability of automated equipment.

The stereoscopic warehouse includes multiple stacker cranes and conveyor systems, which need to operate efficiently in coordination to meet peak order demands during promotions.

Cost Reduction: Labor costs reduced by 45%, and warehouse rental costs reduced by more than 30% due to increased space utilization.

Efficiency Improvement: Inbound/outbound efficiency increased by more than 70%, shelf-life management accuracy reached 100%, and order processing capacity during promotions doubled.

Quality: Stable operation of equipment in low-temperature environments, food loss rate reduced by more than 10%, ensuring food safety and freshness.