Create Time: 06 ,27 ,2025

The Four-Way Shuttle Automated Storage System, with its high-density storage, flexible production line design, and highly scalable in-and-out efficiency, has become a favored solution for logistics companies and manufacturing logistics warehouses.

This high-density storage feature is akin to creating a 3D Rubik's Cube in the warehouse, maximizing the use of limited space, and significantly improving operational efficiency. However, for logistics companies, this high-density storage is not without its challenges.

Since the introduction of the four-way shuttle project, the complexity of equipment connections and the precision requirements have typically limited the storage height to under 20 meters, with many industry suppliers considering anything above 20 meters as a "forbidden zone."

If warehouse height could be increased in the same way as AS/RS systems, it would significantly save land resources and greatly improve storage efficiency per unit area. This would meet the fundamental needs of more logistics enterprises.

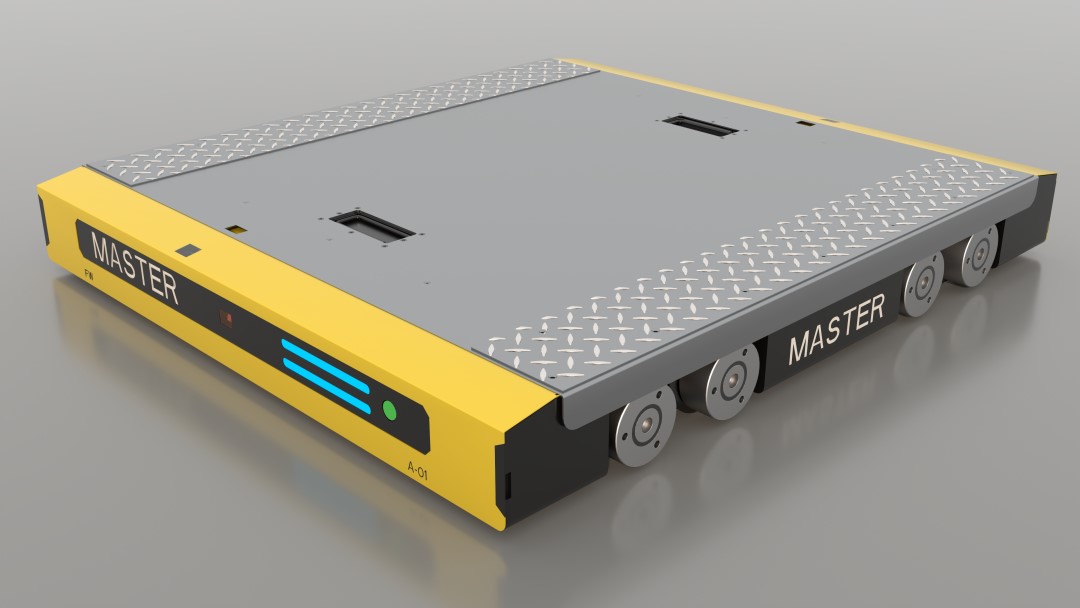

Thanks to the self-researched and self-manufactured components of the Four-Way Shuttle System, Tianjin Master has focused on optimizing equipment connections, particularly the design of high-level lifting mechanisms. The company has poured considerable effort into ensuring smooth operation in high-elevation projects. In fact, the vertical speed of the lift mechanism has been increased to more than double the speed of industry competitors. In recent years, Tianjin Master has taken the lead in tackling storage projects exceeding 20 meters, with several automated warehouses already surpassing this height, and completed projects now exceeding 26 meters.

Recently, good news has come from the overseas market. The overseas team won a bid for a 36-meter ultra-high four-way shuttle project. This achievement not only validates Tianjin Master's technical strength once again, but it also sets a new record for the highest height in the four-way shuttle field. This milestone signals that the warehouse industry is about to experience more possibilities. Higher, smarter, and more efficient storage solutions will gradually become a reality.

Tianjin Master will continue to focus on the logistics equipment industry, strengthening its domestic market presence while steadfastly implementing its "Go Global" strategy. The company remains committed to research and development, creating high-quality products, and demonstrating China's strength in intelligent manufacturing across broader markets.