Customer overview

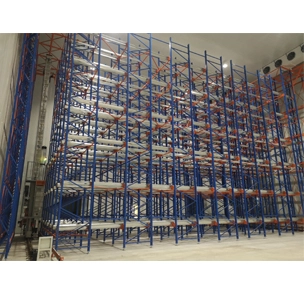

The total number of planned cargo spaces is 7,700 (3,700 spaces for raw material warehouses, 2,000 spaces for normal temperature finished product warehouses, and 2,000 spaces for low temperature finished product warehouses)

One-stop service from consulting, planning, and implementation of general contracting to overall project implementation.

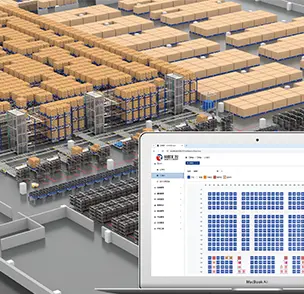

Selected products: 17 four-way pallet shuttles + 12 warehouse elevators + 9 lurking AGVs + 3 unmanned forklifts + 3 full-layer stacking robots.

System configuration: WMS warehouse management system, intelligent and automated hardware-software full process.

This dense storage solution solves the problems of small space in a single warehouse, insufficient number of cargo spaces, and high efficiency requirements for inbound and outbound storage

Systems and Equipment to Discover:

Cooperative docking: The coordinated docking of conveyor lines and elevators is required, and the labor efficiency is low.

Cost investment: Three shifts, repeated ineffective operations, and rising costs year after year.

Flexible logistics: The site space is compact and does not support secondary transformation of the site environment.

Operation efficiency: There is no warehouse information management on site, and the efficiency of picking up and finding goods is slow.

Increase storage capacity by 4.5 times

Increase efficiency by 10%

Reduce 4 workers

Precise docking

All-round safety guarantee