Create Time: 05 ,16 ,2025

4-way pallet shuttle system is a an automated material handling solution elevates automated pallet storage by enabling movement in all four directions—forward, reverse, cross-aisle, and vertical. This intelligent material handling equipment optimizing both horizontal and vertical storage space, and increasing throughput compared to traditional warehouse systems.

1. Four-way shuttle – Automated vehicle that moves pallets in four directions within a rack structure to store and retrieve goods.

2. Horizontal conveying system – An integrated conveyor system that facilitates the movement of pallets or goods between the shuttle racks and the warehouse's entry/exit points.

3. Hoist – a mechanical lift equipment that delivers shuttles and pallets to high storage levels.

Racking system – a high-density structure specially designed to ensure the safe, smooth movement of the shuttle inside it.

Unlike traditional warehouse logistics systems, these 4-way shuttles move forward, backward, left, and right, optimizing both horizontal and vertical storage space.

Step 1: Conveying systems load shuttles and pallets into the designated storage lane.

Step 2: Pre-programmed 4-way shuttle detects optimal storage lane.

Step 3: The four-way shuttle can move forward/ backward along X- axis(surge), left/right along Y-axis(sway) to place pallet.

Step 4: On-demand retrieval for order fulfillment.

l Flexibility: Allowing shuttles to move in multiple directions: forward, backward, left, and right. This multi-directional capability significantly enhances the efficiency of accessing and organizing goods

l Scalability: Multiple shuttles work in parallel. The system meet growing business needs without extensive overhauls

l Efficiency: Four-way shuttle increases throughput significantly, as the 4-way shuttle is 50% faster than forklifts with a very fast delivery time for picking up goods.

Four Way Shuttle AS/RS systems ideal for complex, high-volume storage with massive SKUs, and/or high-throughput demand.

1. Cold Storage: Optimize cold storage with -25°C resistance, high-density automation, fast lithium charging, and WMS integration for efficient frozen goods handling.

2. Food & Beverage Storage: Enhance food & beverage storage by enabling high-density, automated pallet handling with hygienic design.

3. Medicine Storage: Offer precise temperature control (2°C to 25°C), batch tracking via WMS integration, vibration-free operation to protect fragile goods.

4. Apparel Storage: enabling ultra-high-density organization, 3x faster picking, 99.9% inventory accuracy, and gentle garment handling.

5. Retail Storage: enable multidirectional movement across warehouse storage grids.

6. Chemical Storage:

4-way shuttles surpass traditional shuttles in flexibility, storage density, and automation, moving in four directions (forward, backward, left, right) for efficient multi-aisle access without extra transfers. They maximize space in high-density warehouses, reduce labor costs, and adapt easily to layout changes, while traditional shuttles, limited to two-directional movement, require more manual intervention and aisle space. Though 4-way systems have a higher upfront cost, they offer better long-term ROI through energy savings and scalability, making them ideal for automated, large-scale logistics, whereas traditional shuttles suit simpler, smaller operations.

4-way shuttles require less maintenance than traditional systems while delivering superior long-term performance. Their advanced design minimizes wear with smooth multi-directional movement and smart energy management, reducing mechanical stress. Built with durable materials and often equipped with IoT monitoring, they enable predictive maintenance to prevent breakdowns and extend lifespan. Though initial upkeep costs may be slightly higher, 4-way shuttles prove more cost-effective over time due to lower repair needs and consistent efficiency—ideal for warehouses prioritizing reliability and automation.

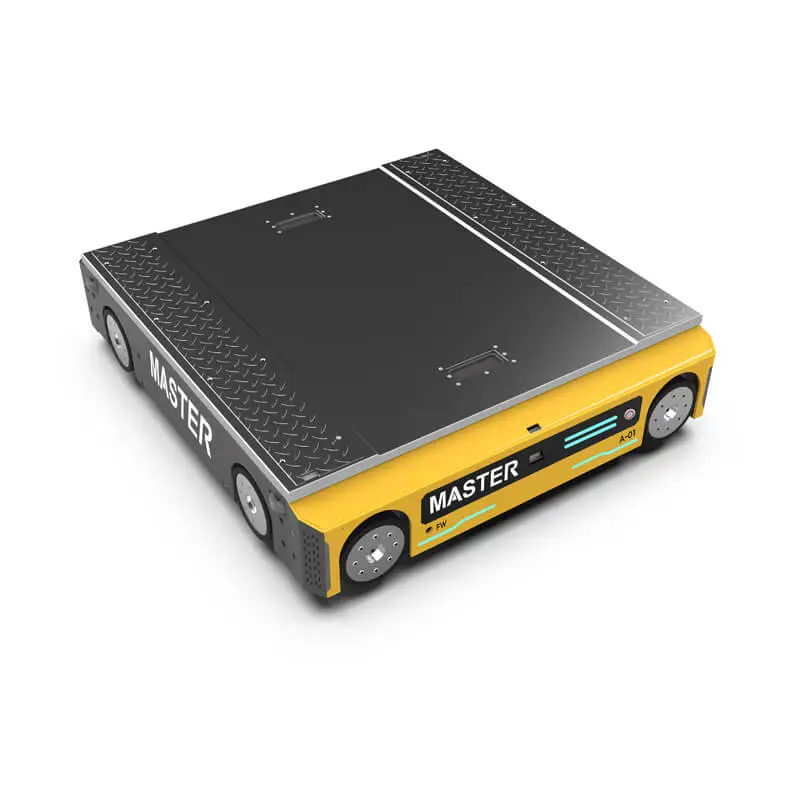

Tianjin Master's 4-way shuttle system stands out as an advanced warehousing solution, offering multi-directional movement (forward/backward/left/right) for superior space utilization and operational efficiency. As showcased on their product page, these intelligent shuttles feature automated positioning, high-speed operation (up to 2m/s), and ultra-precise (±2mm) loading, making them ideal for modern automated warehouses. The system's modular design allows flexible configuration to meet various storage needs, while its energy-saving operation and low maintenance requirements ensure cost-effective long-term performance. With load capacities ranging from 50-1500kg, Tianjin Master's solution delivers reliable, high-density storage perfect for industries requiring efficient material handling.