Create Time: 05 ,21 ,2025

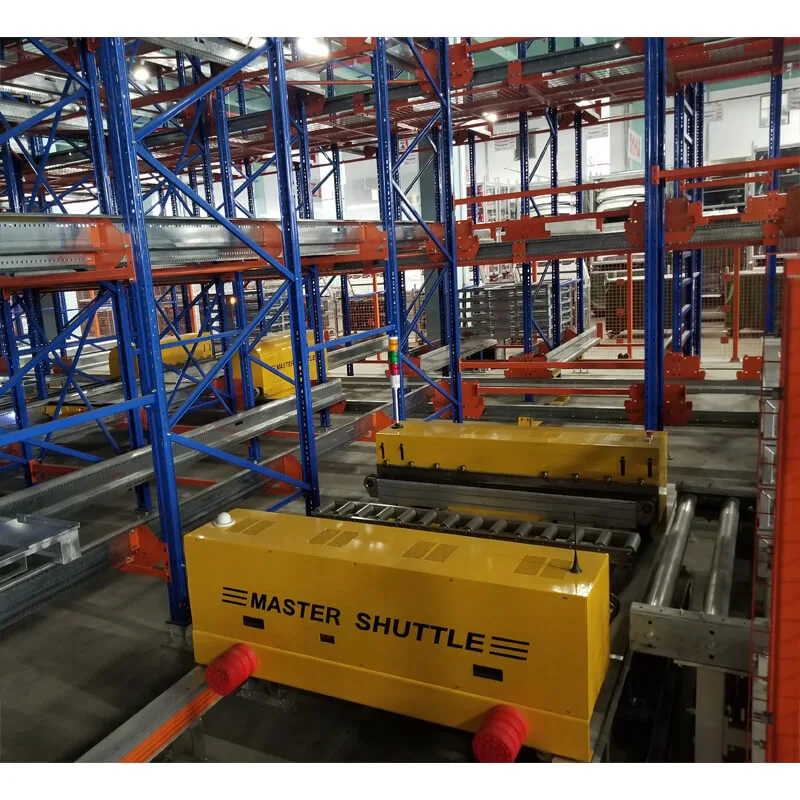

In the fast-evolving world of automation, Rail-Guided Vehicles (RGVs) have emerged as a reliable and efficient solution for material handling. These automated transport systems operate on fixed rails, ensuring precise movement of goods in manufacturing plants, warehouses, and logistics hubs.

RGVs play a crucial role in industries that demand high-speed, repeatable, and error-free transportation, such as automotive, pharmaceuticals, and e-commerce fulfillment centers. Unlike traditional conveyor systems or manually operated forklifts, RGVs offer enhanced efficiency, safety, and scalability, making them a preferred choice for modern industrial automation.

An RGV (Rail-Guided Vehicle) is an automated transport system that moves along predefined rails or tracks to transport materials within a facility. Unlike AGVs (Automated Guided Vehicles), which navigate freely using lasers or magnetic tapes, RGVs follow a fixed path, ensuring high precision and reliability.

Key Components of an RGV Vehicle:

Chassis & Frame – Provides structural support

Drive System – Motors and wheels for movement

Guidance Rails – Fixed tracks for navigation

Control Unit – PLC or software-based control

Sensors & Safety Systems – Obstacle detection, emergency stops

RGVs are ideal for environments where predictable, high-speed movement is required, such as assembly lines and large-scale warehouses.

Movement: RGVs travel along fixed rails, ensuring precise positioning.

Power Supply: Typically electric (via conductive rails or batteries).

Control Mechanism: Fully automated (controlled by PLC/WMS) or semi-automated (operator-assisted).

Rails/Guide Paths – Define the vehicle's route.

Drive System – Electric motors with speed control.

Sensors – Infrared, ultrasonic, or LiDAR for collision avoidance.

Control Unit – Integrates with Warehouse Management Systems (WMS) for real-time tracking.

Loading: Goods are placed on the RGV at a pickup station.

Transportation: The RGV moves along the rail to the destination.

Unloading: Automated or manual unloading at the target location.

Return: The RGV either waits for the next task or returns to a charging station.

Single-Track: Simple layout, best for linear movement.

Multi-Track: Allows branching and complex routing.

Heavy-Duty: For large loads (e.g., automotive assembly).

Light-Duty: For smaller, high-speed operations (e.g., pharmaceuticals).

RGVs can be tailored for specific needs, including specialized grippers, temperature control, or hybrid power systems.

High Efficiency – Faster than manual transport.

Precision & Reliability – Fixed rails eliminate deviation.

Cost Savings – Reduces labor and operational costs.

Safety – Automated obstacle detection minimizes accidents.

Scalability – Easily expandable with additional rails.

Automotive Manufacturing – Moving car parts between assembly stations.

Warehousing – Pallet and container transport.

Food & Beverage – Hygienic material handling.

Pharmaceuticals – Precise, contamination-free transport.

| Feature | RGV | AGV | Conveyor |

|---|---|---|---|

| Speed | High | Medium | Low |

| Flexibility | Medium | High | Low |

| Cost | Medium | High | Low |

| Maintenance | Low | Medium | High |

When fixed, high-speed routes are needed.

For heavy loads requiring stability.

In environments where precision is critical.

AI & IoT Integration – Smarter path optimization.

Energy-Efficient Models – Solar-powered or regenerative braking.

Expansion into New Industries – Healthcare, aerospace, and retail.

RGV systems offer a perfect blend of speed, accuracy, and cost-efficiency for industrial automation. Whether in manufacturing, warehousing, or logistics, RGVs provide a reliable and scalable solution for material handling needs.

Looking for a customized RGV solution? Contact us today to optimize your operations with cutting-edge automation!